Once the order is confirmed, we will purchase the main fabric and auxiliary materials.

(including sweatband material, brim lining thickness and material, buckle, stitching specifications and colors, brand main label, care label, packaging materials, etc.).

After the fabric arrives at the factory, it‘s not directly put into production.

We will count the quantity to ensure accuracy and check the fabric color and texture for deviations, weaving defects, and stains against the confirmed color cards and samples.

We will also check the auxiliary materials for correct size, color, and function.

When the fabric arrives at the factory, we always show it to the customer.

We will use the correct mold before cutting. Once the fabric is confirmed, we will proceed to cutting

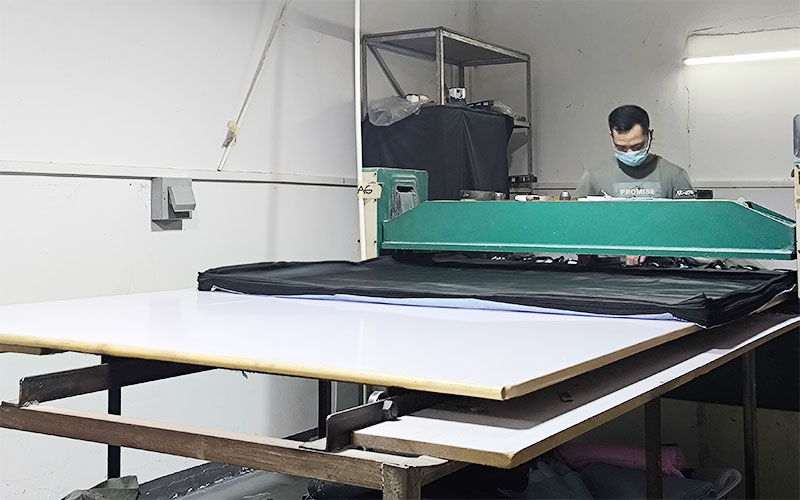

Spread the fabric into many layers on a large cutting table in the cutting room

A computer-controlled (CAD) cutting machine uses a high-speed oscilating blade or laser to cut precisely according to the marker file.

Not all steps are performed simultaneously.

Some custom components can be prepared in advance, such as a printed sweatband, printed inner band, printed woven label, embossed leather, embossed buckles or metal badges, etc.

After the fabrics were cut, the cut front panels are sent to the embroidery department. We have 5 Barudan embroidery machines and 1 small one for embroidery of samples.

Operators hoop the panels, and computerized embroidery machines stitch the design automatically from the .dst file.

For simpler graphics, screen printing, digital printing, heat transfer or washing may be used.

The core sewing process, different worker are responsible for different parts.

We have 3 production lines with approximately 200 sewing machines. Our production manager checks the hat orders that need to be completed on each production line every week.

Each production line also has a supervisor who subdivides the tasks that each worker needs to complete to ensure the smooth production.

We can detail all the steps in making hats in each production line as follows:

Sew different panels to form the crown

Stitch the eyelets of each panel

Sandwich and stitch the visor stiffener between fabric layers

Attach the embroidered or printed panel to the crown.

Attach the visor to the crown assembly.

Sew the sweatband inside the cap.

Sew the interior washing label

Add the top button and attach the closure (metal buckle, plastic snapback, adjustable strap, velcro).

These are just the main tasks, not the complete production process. We also perform many smaller tasks, depending on the style of the hat.

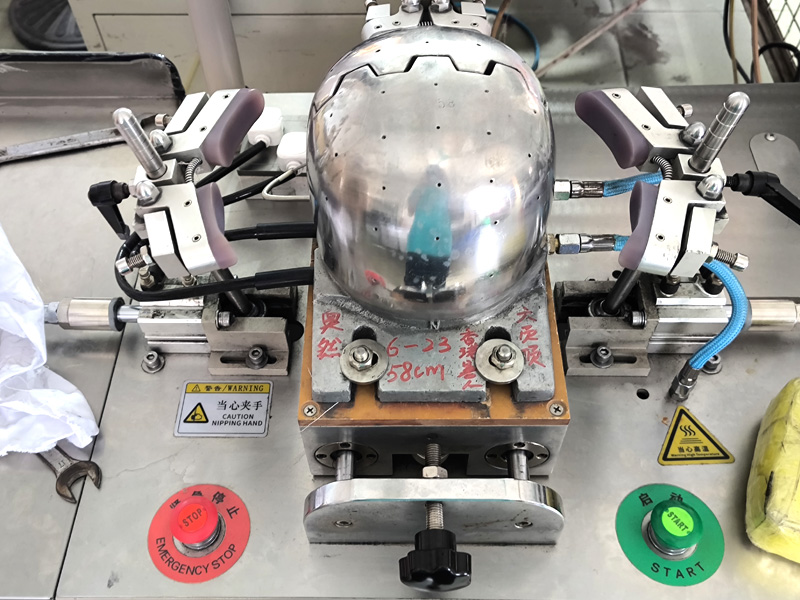

Once the hat is assembled, it's sent through a steamer to achieve the perfect shape.

The sewn cap is placed on a metal or wooden cap form. Steam is injected and high-pressure heat is applied.

This critical step removes sewing wrinkles and gives the cap its full, crisp, and final intended shape.

We use a specialized brim ironing machine for hat finishing, equipped with a heated, curved press plate custom-fitted to the brim's contour.

First, a worker places the hat on the machine's press plate, aligning the brim perfectly. The press plate is preheated to a fabric-safe temperature (adjustable for cotton, polyester, or blends) and then pressed against the brim for 10-15 seconds.

This smooths out wrinkles and creases while also shaping the brim to its desired shape, whether slightly curved or flat.

Once the press is complete, the hat is released from the machine, and a worker immediately inspects the brim for smoothness and consistent shape.

Next, the hat is placed on a slotted conveyor (evenly spaced to avoid friction) for a cooling period with a fan to secure the brim's shape.

It's worth noting that we have separate machines for different styles (baseball caps, bucket hats), ensuring precise and consistent results for every hat.

After Steam Molding and Pressing is completed, hats slide down to a long big table.

Specialized workers use small scissors or a thread-sucking machine to carefully remove all excess thread from the inside and outside of the hats.

This is the core of "trimming." Threads can seriously affect the product's aesthetics and quality.

While trimming the threads, workers will conduct a preliminary inspection of the seams for skipped stitches, missed stitches, and broken threads.

Then workers use tape rollers or high-pressure air guns to remove impurities such as dust, lint, and chalk marks (if any) adhering to the hats' surfaces.

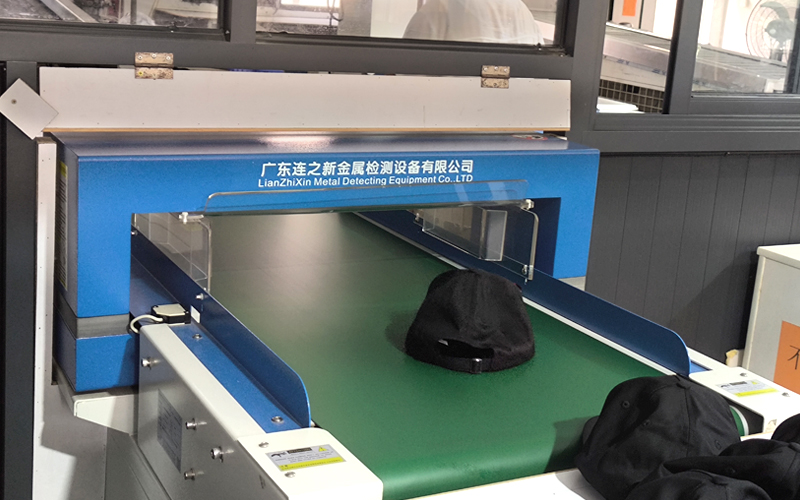

Hats are usually placed on plastic hat forms to retain shape, then packed into poly bags, customized hangtags, product barcode stickers, or placed on hang cards,Hats are also metal-detected using a needle detector to detect any remaining metal objects, such as broken needles or needle tips. significant product liability risks.

If any metal objects are detected, the entire batch must be individually inspected to prevent consumer injury and avoid.

QC team compare the finished goods carefully with the pre-production sample.

They inspector conduct random check during production and full inspections on finished goods.

They check stitching quality, size accuracy, embroidery, cleanliness, symmetry, etc.

Checkpoints:Cut Parts: Check if the edges of the cut fabric pieces are rough or have any flaw points.

Art and Craft: Verify that the pattern is correct, thread colors are accurate, and check for any broken stitches, skipped stitches, or residual backing paper on the reverse side.

Stitching: Inspect if the stitch density (stitches per inch, SPI) meets the standard, ensure the seam is flat and even, and check for any gaps, missed stitches, or double stitching.

Construction: Check the symmetry of assembled components (e.g., if the visor is crooked) and whether the sweatband is sewn on smoothly and evenly.

Cleanliness: Examine the fabric for any stains or soiling.

Packing:Finally, the packers put the goods into inner boxes according to the customer's packaging requirements, write the shipping mark information on the inner boxes, and load the goods into the truck.

As shown above, we have a very rigorous and complete production process for high-end hats.

We have multiple levels of quality control to ensure that the quality of our products is superior to others.

Our prices are not the lowest, but if you are looking for a mid- to high-end hat manufacturer to customize hats,

we strongly recommend that you try us to confirm our strength as an excellent hat manufacturer.

Contact